|

|

|

Cutting Edge U-2S Cockpit |

HyperScale is proudly sponsored by Meteor

Productions

As I mentioned in my

U-2R/S / TR-1A Cockpit Review, this project was started some years

back when Cutting Edge first released all their original

conversions, updates, and decals for the U-2R/S / TR-1A. Without a

cockpit set, though, I was not up for completing the kit and re-boxed it

to await the release of a resin cockpit set. When Cutting Edge

released their resin cockpit set in the end of 2002, I dug out the kit

and re-started it.

On all of my current projects, I tend to be writing my model postings

at the same time as I build the models. This posting has been reworked

several times as the project changed its focus. Originally, I was

planning a very simple build with a replacement resin cockpit, resin

nose, and resin Senior Span/Spear upgrade. These were all simple,

drop-in additions that required almost no surgery to use.

Then, I got more into the project and ended up going hog wild on

detailing, scratch building all sorts of details on the model. I have

never claimed to be unaffected by AMS (Advanced Modelers Syndrome), I

just seam to be able to work through it when the bug bites me hard. This

posting swelled into a monster five-part posting detailing all sorts of

scratch-building items for the U-2R/S.

Then, a HyperScale friend convinced me that all these scratch-built

items should get cast into resin so that others (espescially him) could

use them, too. To that end, the scratch-built stuff became masters for

Cutting Edge to use to market some more U-2R/S resin update sets

in their already extensive resin line. To see more about the

scratch-building I did on the masters for the Cutting Edge sets,

see the reviews I wrote on those sets. This posting will only deal with

the usage of those sets in the Italeri U-2R/S kit.

The outcome of all this reworking of my writing is now a three-part

posting. The writing is not as long as when I had all the

scratch-building work highlighted. This is the first part and deals with

a brief history of the U-2S "Dragon Lady", a review of the Testor/Italeri

kit, and the construction of inside portions of the fuselage using lots

of resin goodies. The second part will come along later and detail the

exterior of the fuselage, the construction of the wings, and the

completion of the airframe construction. The final part of the group

will detail the painting and finishing of the model.

A Brief U-2 Family History

First, let's do a little historical writing on the U-2. This is a

very brief (and vastly over-simplified) review of the U-2 development

history. In the beginning, there was the U-2A. With an engine upgrade,

many of these were redesignated to U-2C. Further modifications to the

U-2C created the U-2E, U-2F, U-2G, and U-2H. The U-2D was a

factory-built two-seat U-2, basically equivalent to the U-2C. A couple

U-2A/C aircraft were also re-manufactured into two-seat aircraft and

designated as U-2CT. As the sensor systems got heavier and bulkier to

carry, the performance of the U-2 started to suffer quite a bit. An

upgraded U-2 was needed.

Answering the call, Lockheed revised the U-2 design and increased it

in size (both in length and width) with the new aircraft being

designated U-2R ("R" for "Revised"). As attrition and combat losses

mounted, the Air Force determined they needed more U-2R aircraft. To

distance the additional aircraft from the "black-ops" reputation of the

U-2 designation, they designated them as TR-1A (two-seat TR-1B). These

were basically carbon copies of the U-2R.

In time, the logistics of supporting two mostly identical airframes

with two designations got to be a problem. Also, the TR-1 designation

failed to distance the new aircraft from the "black-ops" reputation of

the U-2 designation. In 1991, to solve the logistical issues, all TR-1A

aircraft were re-designated to be U-2R aircraft. The TR-1B became the

U-2RT.

The U-2S designation came along in the 1990s when the surviving U-2R

aircraft were upgraded with newer engines. According to most references,

all U-2R aircraft are now U-2S aircraft. The upgrade has almost no

outward feature to tell whether an aircraft is a U-2R or U-2S. The

deletion of two small air louvers on the fuselage over the wing root is

the only way to tell for sure that a given aircraft is a U-2S.

I saw the U-2S aircraft in the picture below at the 1996 Andrews AFB

air show. It inspired me a lot and is the reason I decided to built the

model you see in this posting. I knew very little about the U-2 before

starting this project, so I needed to do more research on this aircraft

than I have had to do on any of the other projects I have completed in

the last few years.

Figuring I was not the only person with limited U-2 knowledge, I

created a reference web page for the U-2S. I have also written quite a

bit more in this construction feature than I typically do. My hope is to

save other modelers from having to search as hard as I did for this

information.

U-2S at the 1996 Andrews AFB Air Show —

Click the Picture to View My Reference Page on the

U-2

For more information on late model U-2 aircraft, see my reference

list at the end of this posting.

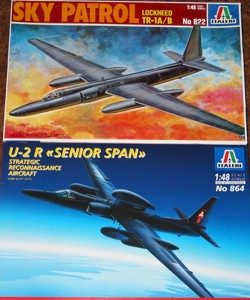

The Testor / Italeri late model U-2 kits have been marketed a

few times as different designations. One of the original releases from

Testor called the kit a "Lockheed TR-1A". Another release was

from Italeri and was for a TR-1A/B "Sky Patrol". Both these

releases contain identical plastic components to each other, only the

instructions and decals changed. Both these releases provide alternate

pieces for building either a single seat U-2R / TR-1A or a two-seat

U-2RT / TR-1B. The super pods in these kits are smooth and regular with

no sensor systems represented.

|

Caveat

I have defended

Testor/Italeri's late model U-2s as being good kits on the

HyperScale Forum, and I stand by that assessment.

Built

out-of-the-box, nobody would miss the fact that this is a late

model U-2 "Dragon Lady". However, that does not mean the kit is

perfect. There are notable accuracy issues and ommissions with

several points in the kit, but most all of these amount to details

that only a U-2 crew chief might see. Indeed, it took me weeks of

research to find out all I have concerning the U-2 and apply my

findings to the model.

What I write from here out about all the things I fixed or changed

on the kit relates to myself wanting to stretch my legs and take

on some challenges. The kit for the most part, except for the

cockpit, would be quite acceptable out of the box. |

The Testor / Italeri late model U-2 kits are actually not bad

kits on their own. They were above average when they were released in

the early 1980s. They require some care in construction, have a few fit

problems, and are a bit "soft" on some details, but overall they are not

bad. Built out-of-the-box, they are plausible representations of the

late model U-2 as it looked in the 1980s. They do not provide any of the

more common sensor fits seen on current U-2 aircraft.

The scribing is the raised variety, which turns some modelers off,

but it is petite enough for my taste. The accuracy of the scribing is up

for grabs, though. Italeri had very little information to work

with when they originally tooled this kit. They got as close as they

could with very limited and (in some cases) sketchy data.

And, let me stress that the constructed model is HUGE! The

wingspan is a very impressive 26 inches when done. This caused me to

have to think of unique ways to display the model on my shelves, but

that is a different story...

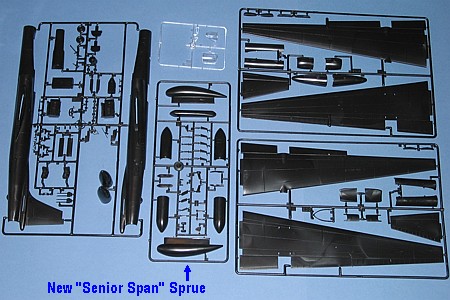

The latest release of this kit is from Italeri and is for a

U-2R "Senior Span". This release differs from the earlier ones in that

it deletes the two-seat option and provides an extra sprue tree with all

the updates to build a Senior Span/Spear/Ruby aircraft. The extent of

updates provided on this extra sprue caught me by surprise. I was

initially going to build the "Sky Patrol" release of the kit, which I

had picked up back in 1996. After acquiring the "Senior Span" release,

just out of curiosity over the new pieces, I decided that I would build

it instead of the "Sky Patrol" kit.

Just looking at the box art before I opened the "Senior Span" kit, I

noted both Senior Spear and Senior Ruby installations on the aircraft as

well as other airframe updates that I knew were not in the "Sky Patrol"

release of the kit. Would all these be in the box?

In a word -- YES! The new sprue tree was much larger than I expected

and provided the Senior Span/Spur dorsal antenna pod, the Senior Spear

super pod antenna canoe with ventral antenna farms, and the Senior Ruby

flattened super pod sides. Additionally, there were a number of airframe

updates included to provide the GPS antenna on the left wing and the ECM

dimples on the engine entake sides. Besides removing the parts for the

two-seat aircraft, another change to the original "Sky Patrol" sprues

was the deletion of the standard super pod nose cones. This then forces

the build of only a Senior Ruby updated aircraft from this kit.

Other new parts found only in the "Senior Span" kit relate to very

early airframes, also. These include an alternate tail top without any

ECM fairing, an alternate ADF antenna for the spine, and

alternate/different style ECM pods for the wing tips. Expect to see a

very early U-2R released from Italeri at some point in the

future.

The Testor "Lockheed TR-1A" and Italeri "Sky Patrol"

kits are both comprised of 85 pieces. The "Senior Span" kit deletes 5

pieces from the kit associated to the two-seat option and the standard

super pod nose cones. It then adds 41 pieces to the kit on a new sprue

that provides all the new airframe upgrades, bringing the count of

pieces up to 121 in the "Senior Span" release. Everything is molded in

black styrene (with clear canopy pieces). I would prefer the more

standard gray colored plastic because the black color makes it hard to

see molded details and imperfections, but I had to make due with what

Italeri provided.

Italeri Box Art |

"Senior Span" Kit Sprues |

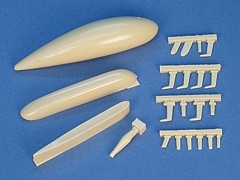

Cutting Edge 1/48 Scale

U-2 Update Sets

|

I used six different Cutting Edge update sets on this

model as shown in the following pictures. I have some personal pictures

I took at the 1996 Andrews AFB air show of a Senior Span/Spur/Spear U-2S

and wanted to build that same aircraft. These sets provided me all the

necessary updates to do this (and then some). Indeed, Dave Klaus at

Cutting Edge confirmed to me once that this exact aircraft (from the

1996 Andrews AFB air show) was a major source for the documentation that

went into the Cutting Edge Senior Span/Spur/Spear update set and

ASARS II nose.

Senior Span/Spur/Spear Set

(CEC48104) |

ASARS II Nose

(CEC48106) |

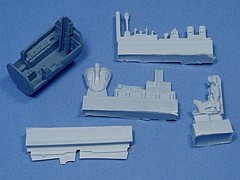

Cockpit Set

(CEC48409) |

Wing Correction Set

(CEC48441) |

Fuselage Update Set

(CEC48442) |

Engine Exhaust Set

(CEC48443) |

All the sets are quite nice. For full reviews of each set, click on

the photos above.

At this point, you might be trying to add up the cost in your head

for all these sets. Let me help you out. Altogether, these sets amount

to just over $100.00 USD (as calculated from the prices listed on the

Meteor Productions web site). Add some Cutting Edge decals (which

I did for my model) and the cost rounds out to about $110.00 USD. All

this is for a kit that you can find at swap meets for about $12.00 USD

(the early, non-Senior Span releases).

Whether all this is worth it for any kit is a decision between each

modeler and his wallet. For me, the answer is, "Yes, absolutely".

Your opinion may vary, though.

I started tinkering with this kit almost five years ago. When push

came to shove and I was ready to start work on the fuselage, I found the

kit cockpit rather simplistic and lacking in details. I figured that I

could start scratch building a new cockpit, or I could put off building

the kit in hopes that someone would release a resin cockpit update. A

brief talk with Dave at Cutting Edge confirmed they eventually

were going to do a cockpit set. So, I re-boxed the kit and placed it on

the "inactive pile" to await a resin cockpit set.

Now, roll the clocks ahead four and a half years.

Eventually, Cutting Edge released the U-2R resin cockpit

update set. It is a really great cockpit set and immediately had me

wanting to dig out the old U-2 kit which was still sitting in the

"inactive pile" in my closet. Check out my cockpit review to see how

easily the resin cockpit dropped into the kit. By the time I had

finished writing the cockpit review, I already had the cockpit

integrated into the U-2 kit and ready for paint.

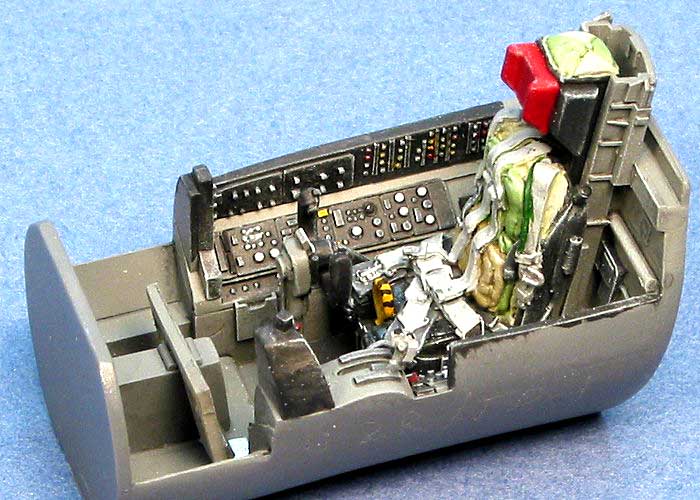

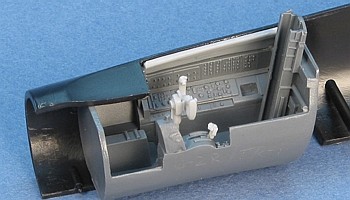

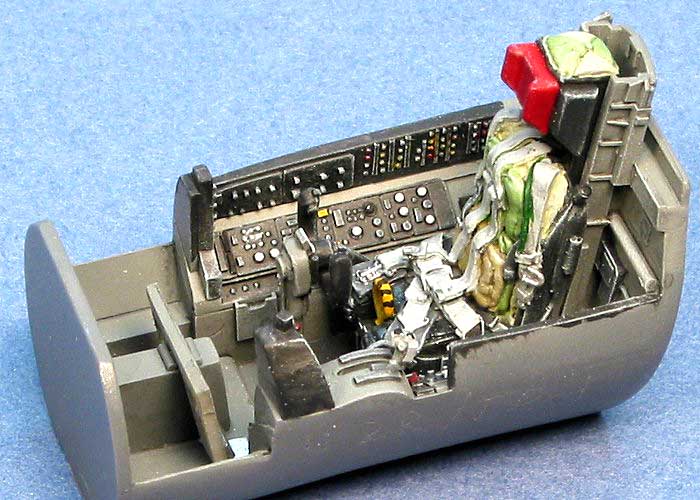

Cockpit |

Ejection Seat |

Main Instrument Panel |

From photographs, U-2R (and presumably U-2S / TR-1A) cockpits appear

to be Dark Gull Gray (F.S.36231). I painted the entire cockpit in this

color, then picked off the instrument panels with Interior Black.

Various details were painted yellow and red and I dry brushed the whole

cockpit in Light Ghost Gray (F.S.36375). Pictures showed the ejection

seat to be black, so I painted the whole thing in Interior Black. The

rear cushion is a green-gray color and the lower cushion appears to be

black leather. I painted the seat harnesses in Light Ghost Gray

(F.S.36375). I know -- cloth items do not have F.S. numbers for color,

but I find this color best captures the color of the sort-of metallic

looking silver/gray cloth from which many seat harnesses are made.

With the cockpit painted, I mounted it inside the right fuselage

half.

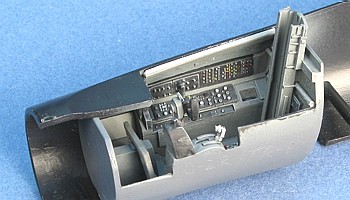

Cockpit |

Ejection Seat |

Main Instrument Panel |

Next, I turned my attentions to the main wheel bay. The Italeri

representation of this area is complete fiction. The kit piece is not

even deep enough to hold the wheels if they retracted. Fixing this

shortcoming lead me down the path that eventually had me scratch-build a

new wheel bay and provide it to Cutting Edge so they could use it

in thier U-2R/S Fuselage Update set.

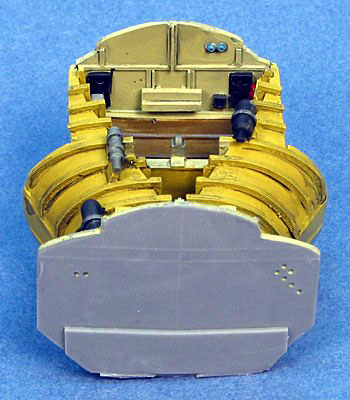

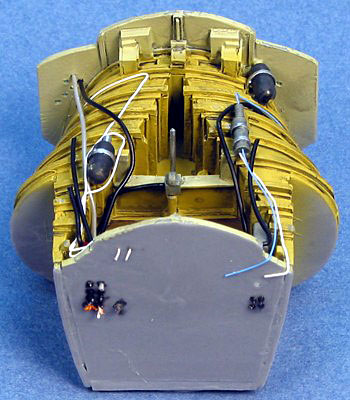

I removed the slag from the Cutting Edge wheel bay unit and

painted it according to the colors stated on the instruction sheet. For

the weird light greenish color, I was speaking with a friend in my model

club, Ed. He said the color reminded him of the green color in the new

Israeli camouflage (like on the F-15I). I had to agree, although I had

not made that connection myself. I compared this color (F.S.34424) to

the color pictures I have, and sure enough, it was a pretty close match.

Hence, the areas of the wheel bay and the engine intakes that required

this color were painted using F.S.34424 from the old Floquil

Military Colors paint line.

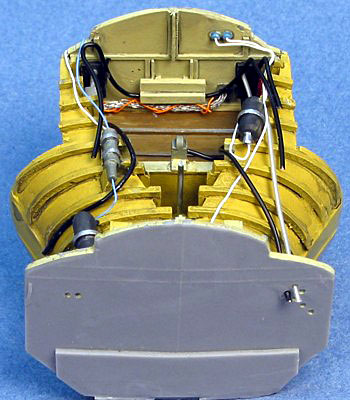

Referring to documentation pictures, I added some varying colors of

wiring to the bay that were not part of the cast piece. Because the

wires stand well away form any of the inner surfaces, having them cast

in place was not feasible and still look right to me. Using pre-colored

ignition wires for 1/24th scale car

models, the job of wiring the wheel bay went fast. There are

flashed-over holes in both bulkheads of the wheel bay to assist in

holding the wiring in place. I just re-drilled these open and added the

pre-colored wiring to match what I saw in the pictures.

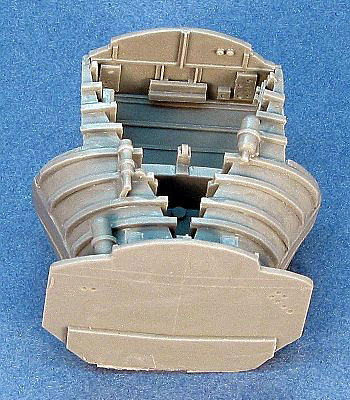

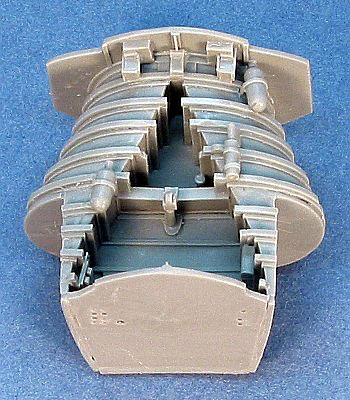

The following series of pictures traces the wheel bay from raw resin

to installed wheel bay.

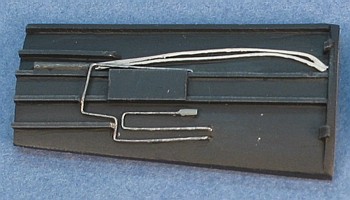

Unpainted Wheel Bay |

Unpainted Wheel Bay |

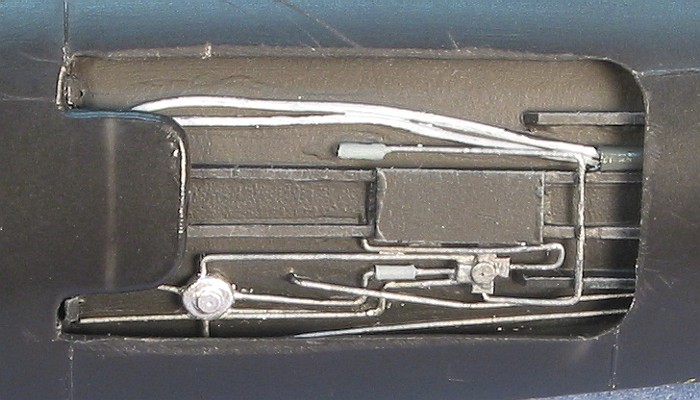

Painted Wheel Bay |

Painted Wheel Bay |

Completed Wheel Bay |

Completed Wheel Bay |

Completed Wheel Bay - Installed |

Completed Wheel Bay - Installed |

The only detail items on the U-2R/S airframe not covered in the

Cutting Edge update sets are the speed brakes. They did ask me to

create a set for these, but the complexities of creating all the piping

in the wells and still have it be cast-able got the best of me. I found

myself drifting away from the project because I did not want to deal

with it. I decided to drop the idea of creating masters and just created

some speed brake details for myself. Sorry guys...

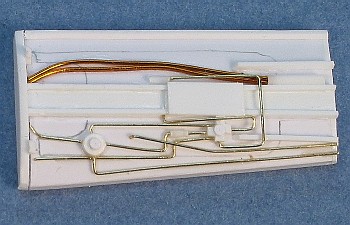

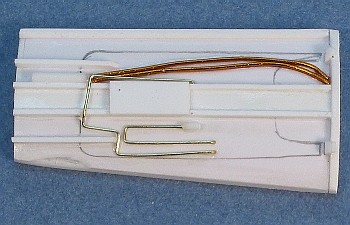

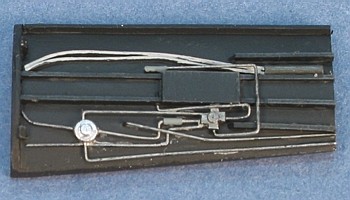

I completely cut away the kit-provided speed brake wells and

scratch-built new ones from sheet and strip styrene. I detailed the new

wells using assorted sizes of brass and copper wire. The speed brake

wells on the U-2R/S are not really "wells" and are more "bays". That is

to say they really do not have walls to box them off. They are backing

walls with assorted ribbing and plumbing that are mostly open all the

way around the speed brake opening on the fuselage. The images below

show the completed wells before and after painting.

Left Speed Brake Wells - Unpainted |

Right Speed Brake Wells - Unpainted |

Left Speed Brake Wells - Painted |

Right Speed Brake Wells - Painted |

With the bays completed, I used my Dremel tool to remove the kit-molded

details inside the speed brake doors. I rebuilt the details using more

sheet and strip styrene. With the doors done, I could then measure the

precise length for the brake actuators and scratch-built these from

styrene rod and brass wire. All painted and finished, the final speed

brakes looked much better than the kit-molded version.

Installed Left Speed Brake |

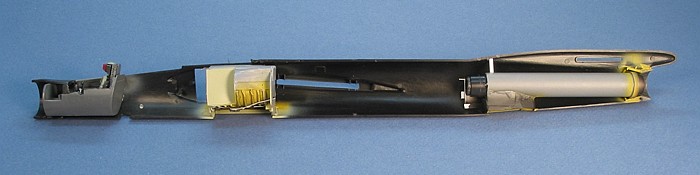

The engine on the U-2 is buried deep inside the airframe with a

rather lengthy tail pipe to reach all the way to the engine exhaust

point under the vertical tail. The kit piece for the tail pipe is about

1/4" deep and includes details on the inside that are intended to

represent the rear turbines of the engine. Cutting Edge's exhaust

pipe corrects this area of the the kit with a unit providing a much more

realistic depth to the engine exhaust.

I painted and installed the replacement engine exhaust following the

Cutting Edge instructions.

The kit tail landing gear strut needed some minor detailing added to

represent the rigging used to steer the aircraft when it is on the

ground. I added these details and installed the strut into the wheel

well that is molded as part of the engine exhaust piece.

Engine Exhaust |

Tail Wheel Well |

With all the update sets installed, the inside of the fuselage was

getting to be a very busy place. I finally could assemble the fuselage

and move on to other areas of the model.

This completed my major construction work inside the fuselage. I had

a lot more to do to the exterior of the fuselage and big plans for the

wings, so I decided these areas deserved their own posting to describe

what I did. Look for the fuselage completion, the wing construction, and

the assembly of the complete airframe in part two of my U-2S "Senior

Span/Spur" project postings.

(Newest to Oldest)

-

U-2R/S Walk Around by David W

Aungst

On-Line HyperScale Reference, 2003

-

U-2: The Second Generation by

Chris Pocock

World Airpower Journal, Volume 28, AirTime Publishing, 1997

-

Dragon Lady by Ted Carlson /

Toyokazu Matsuzaki

Koku-Fan Magazine, Volume 1996-04, Bunrin-Do Company, Limited, 1996

-

Recce Tech by Paul F Crickmore

Osprey Color Series, Osprey Aerospace Publishing, 1989

-

U-2 Spyplane in Action by Larry

Davis

, Squadron In Action #86, Squadron Publishing, 1988/2002

-

Lockheed U-2R/TR-1 by Jay Miller

AeroFax MiniGraph #28, AeroFax, Inc., 1988

-

Lockheed U-2 by Jay Miller

AeroFax AeroGraph #3, AeroFax, Inc., 1983

Model, Description and Images Copyright ©

2003 by David Aungst

Home |

What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search